In external mix set-ups, the air and liquid streams exit the nozzle separately and are mixed externally. As the air and liquid lines within the nozzle are not connected, the flow rates of air and liquid can be controlled independently, enabling precise metering of the liquid. Adjusting the air flow rate can control atomization, with higher airflow producing finer atomization. However, external mix setups may not produce as fine atomization as internal mix setups.

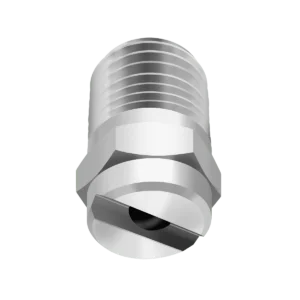

External mix air atomizing spray nozzles are suitable for use with liquids of high viscosity, with the ability to work with liquids above 250 cP. These nozzles have the highest flow rates and allow for independent adjustment of air and liquid flows, making them ideal for applications where precise liquid flow control is crucial. Our air atomizing nozzle models can fit a 1/4 male connector (with a 1/4" female size) and are constructed from SS316 material, with other material options available, including brass, SS304, and Duplex steel, based on customer requirements.

Atomizing nozzles for viscous fluids offer increased control of spray pattern and droplet size independent of the shape of the air or atomizing air and control air. These nozzles are externally controlled and come with a built-in pneumatic control valve for improved control. They are ideal for applications that require increased spray nozzle control.