TANK MIXING NOZZLES

Tank Mixing Nozzles, also known as Tank Mixing Eductors, can function as an alternative or addition to mechanical agitators. They are effective in introducing and mixing a new fluid with an existing fluid, and are less expensive to operate and maintain in comparison to the equipment they replace. This is especially significant for applications that require materials with special corrosion-resistant properties. Liquid tank mixing nozzles optimize the mixing ratio of liquids and are more efficient than pipes with holes. Venturi eductor nozzles come in various designs, sizes, and materials, and can be customized to fit the type of liquids, tank sizes, and shapes.

● Ensuring a uniform mix of fluid throughout the tank, leading to consistent product and process quality.

● Eliminating sludge and slurry build-up, which reduces tank cleaning time.

● Using small and efficient pumps to circulate large volumes of tank solution, achieving an effective turnover rate.

● Being easy to operate and maintain as there are no moving parts.

● Eliminating the need for compressed or blower air, which can cause oil contamination or ventilation problems.

● Chemical injection and liquid mixing

● Blending ethanol and bio-diesel

● Anodizing tanks

● Cleaning

● Electroplating tanks

● Sludge tanks

● Paint booth applications

● Phosphating

● Plating tanks

● Rinsing

● Stripping applications

● Large flow opening that allows particulates to pass through with minimal clogging.

● Flow chamber design that eliminates internal material build-up.

● Compact design that minimizes interference with plating racks and other in-tank equipment.

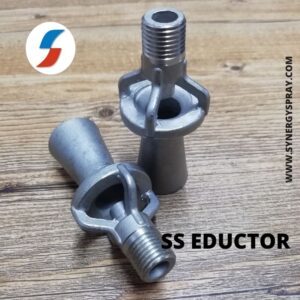

● Wide range of material options such as PVC, stainless steel, PVDF, and nylon.

● In-tank mounting design that eliminates the need for above-tank mounting devices.

● Mounting accessories that simplify installation and allow easy, precise adjustment of eductor flow.